—You’ve now partnered with Fukushin Electric to develop an original feeder for JDP. How did that collaboration come about?

Ryuichi: I visited Fukushin Electric and was given a factory tour. It was the place that truly represents the spirit of “Made in Japan.” What surprised me was that, while there are various regulations and standards involved in manufacturing, such as HACCP and ISO, I saw some posted on the walls that even I, as a manufacturer, had never seen before.

—Interesting. In the Nishikigoi world, Fukushin Electric is well-known for the “Feeding Master,” but the company’s primary business is in automobiles, housing, industrial equipment, and aerospace technology, isn’t it?

Ryuichi: Exactly. It holds specialised certifications, such as licenses to manufacture aircraft parts and permits for automotive components. Moreover, it was the cleanest factory I’ve ever seen in my entire life. Seeing the facility firsthand made me realise that this company is not primarily focused on manufacturing and sales, but specialises exclusively in manufacturing.

I directly proposed that our company handle sales and after-sales support, and the president of Fukushin Electric gladly accepted the offer.

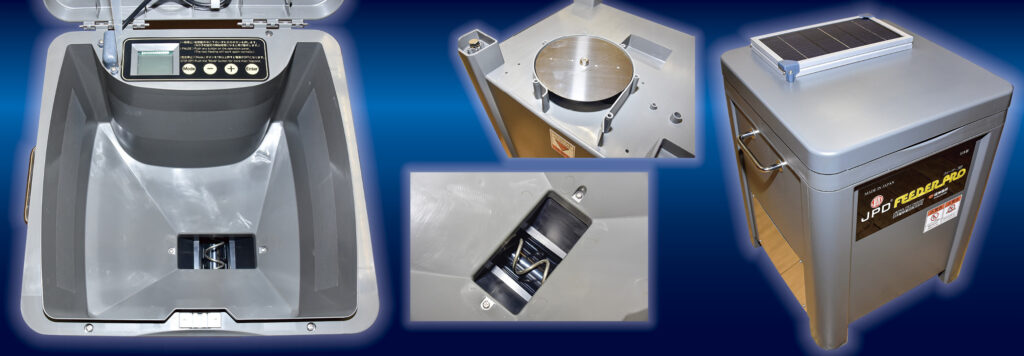

—What are the main differences between JPD’s original “Feeder Pro” and the “Feeding Master”?

Ryuichi: The “Feeding Master” is a well-established product used in the Nishikigoi industry for many years, so we kept its core functions intact. However, we improved the details—for example, we redesigned the dial, which had been prone to malfunctions. The moulded colour is also slightly darker than that of the Feeding Master. In addition, we plan to offer a range of practical accessories to improve usability, such as mounting stands and protective parts designed to prevent damage from bears, a growing concern in recent years.

—I’ve heard that there are plans to increase the size of the solar panel as well. Could you tell us more about that?

Ryuichi: We’re developing JPD’s own circuitry and circuit board to make the product highly customisable—similar to a Mini 4WD toy car—by enabling upgrades like a larger solar panel and other modifications.

—Will there still be two power options: solar for outdoor use and AC power for indoor use?

Ryuichi: Besides those features, we are also developing a dual-purpose feeder that can switch between solar and AC power. By making it compatible for both uses, even if you stop using it in an outdoor pond, you can still use it inside a greenhouse, and it can be used anywhere without location restrictions. We plan to sell it in early June, so please look forward to it.

—What surprised me this time is that JPD handles all repairs and maintenance.

Ryuichi: Our greatest strength is “mobility,” so if we are going to sell feeders, we believe it’s necessary to go that far. While Fukushin Electric has been responsible for repairs and maintenance, staffing constraints have sometimes led to extended response times. For breeders and distributors, feeders are a lifeline in fish farming. To ensure prompt after-sales service in the event of a malfunction or maintenance, we establish a system that allows faster response by stationing our dedicated technicians in Niigata.

—That sounds reliable.

Ryuichi: As a feed manufacturer, the product that best complements our feed sales is the feeder. We sell feeders alongside our feed, and by providing solid after-sales support, we create a synergistic effect that leads to repeat feed purchases. There’s nothing better than being able to help koi dealers by taking care of the problems they’ve been struggling with.

Currently, our fastest-growing feed is starter feed. Feeds for fry and those administered after the fourth culling until pond harvest are selling well. So, feeders are definitely used. That’s why selling feeders is a perfect fit for us, and we’re grateful for the opportunity to do so.

—I believe JPD’s greatest strength lies in having sales representatives across the country who can directly listen to feedback from the field. Given the established “Feeding Master” product, you must ensure you don’t compete directly with it.

Ryuichi: Engaging in price competition is meaningless, so we must differentiate our products from original offerings and focus on creating user-friendly designs.

—Are you planning to introduce feeders to hobbyists in the future?

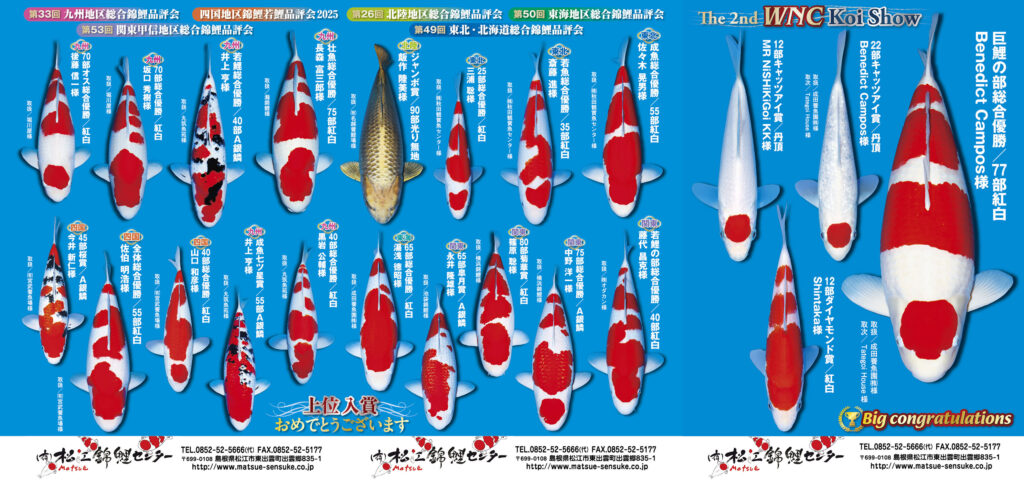

Ryuichi: Yes, that’s right. By setting up booths at the All Japan Combined Nishikigoi Show and promoting our products, hobbyists have shown interest, and we’ve already received several orders. We hope to have many people, both professionals and hobbyists, use our feeders.

—How can hobbyists purchase the feeders?

Ryuichi: We don’t sell directly to hobbyists; we guide them to purchase through our trusted koi dealers. By selling through them, the breeders can also profit.

—We can anticipate significant advancements in koi breeding and keeping practices by fostering a strong partnership among manufacturers, dealers, and hobbyists.

Ryuichi: We aim to provide comprehensive service from sales to after-sales support, including feed supply. While we cannot compete on price for the feeders, we’ve obtained permission from Fukushin Electric to run promotional campaigns focused on feed sales. For instance, we can offer a package deal where customers who purchase the “Feeder Pro” receive feed included. Compared to our previous approach of selling feed alone, this strategy allows us to expand our sales methods and outreach. And feeders are highly effective tools for koi dealers, and we leverage the synergy between feed and feeders to enhance our offerings.

—It’s exciting that a dual-purpose feeder equipped with solar panels and an AC power option will be released in early June.

Ryuichi: We launched the ‘JPD Dream Koi Pond Project’ last summer. With automatic and manual feeders, we aim to raise koi over 90 centimetres!

—We would like to conduct a follow-up interview regarding the ‘JPD Dream Koi Pond Project’. We look forward to speaking with you again.